Carbon Steel Investment Casting

Product Description

https://www.ytc-foundry.com/carbon-steelalloy-steel.html

Carbon Steel Investment Casting

Carbon steel is a steel alloy with carbon as the primary alloying element. Cast alloy steels have been developed for use in conditions requiring higher pressure, wear resistance and higher strength, as well as higher toughness and hardenability. The mechanical properties of this alloy are determined by the percentage of carbon; the higher the percentage, the harder and stronger the alloy becomes through heat treatment. Because carbon steel can be machined to obtain a variety of properties, it can be used in a variety of applications.

Both medium and low carbon steels are used in investment casting. Medium carbon steel has good ductility, strength and wear resistance. It can also be hardened and tempered by heat treatment. Mild steel is easy to form but cannot be strengthened by heat treatment. As an alternative, carburizing can be used to increase the surface hardness of the alloy.

Advantages of carbon steel castings

Carbon steel castings are commonly used due to the low cost of the material and the variety of material grades.

It is widely used in different industries.

Particularly suitable for motors and appliances due to its ferromagnetic properties.

Carbon steel is safe and durable with high structural integrity.

Carbon steel casting process

Carbon Steel Investment Casting

Carbon steel investment casting is the traditional method of pouring carbon steel material using investment casting. In recent years, we have carried out large-scale updates and upgrades, adopting the most advanced silica-sol shell-making technology. We have also introduced an innovative process that combines coated sand with shell making, further optimizing the shell making process to reduce production time and improve surface finish. Examples of carbon steel investment cast parts typically include carbon steel investment cast railroad parts and carbon steel automotive parts.

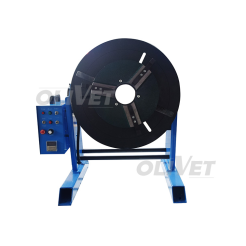

Carbon Steel Shell Mold Casting

Carbon Steel Shell Mold Casting is a new method of shell casting carbon steel casting. The Yitai shell casting line is fully automated to ensure production efficiency and product quality.

Silica Sol Casting

Another lost wax casting method for carbon steel castings. This casting process allows carbon steel castings to be controlled within tolerances CT5-6. The surface finish is much better. The only consideration in choosing this process is its high production cost. We recommend this process if you have high demands on your carbon steel castings.