Electric Heat Tracing Design

Multiply the base heat loss of the pipe from Step 2 by the insulation compensation factor from design manual to get the total heat loss per meter of pipe ,the purpose of EHT is to compensate the heat loss.

Product Description

Electric Heat Tracing Design

► Design Content

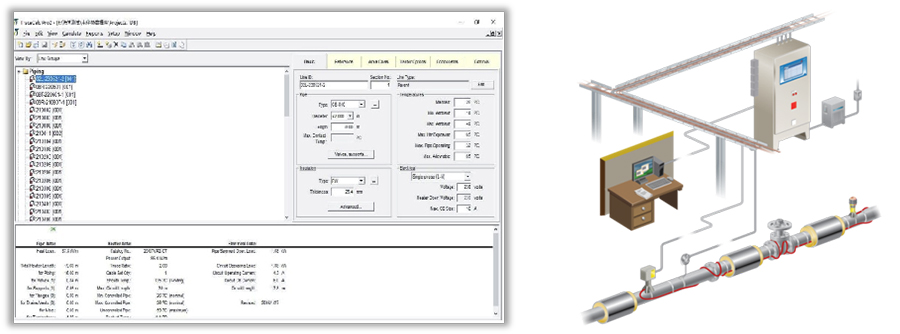

﹡ Type of Selection

﹡ Circuit Design

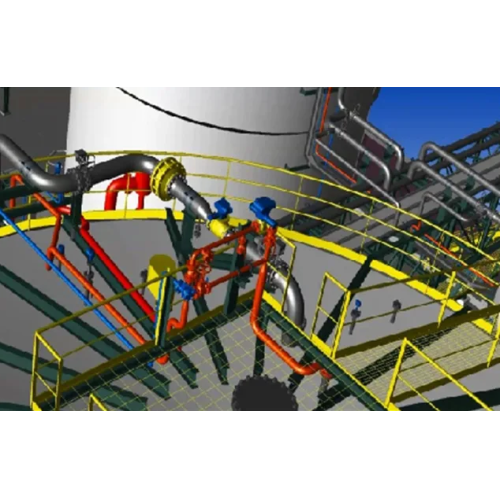

﹡ Layout Drawing

﹡ System Distribution Design

﹡ Calculation Software

Thermal Design- Pipe Heat Loss Calculations and Heating Cable Selection

►Pipe Heat Loss Calculations

﹡Step 1 Calculate temperature differential △T = TM – TA

﹡Step 2 Calculate the pipe heat loss.

From design manual to find the base heat loss of the pipe.

(The indoor heat loss will be multiplied 0.9)

﹡Step 3 Compensate for insulation type.

Multiply the base heat loss of the pipe from Step 2 by the insulation compensation factor from design manual to get the total heat loss per meter of pipe ,the purpose of EHT is to compensate the heat loss.

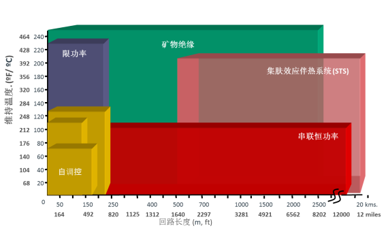

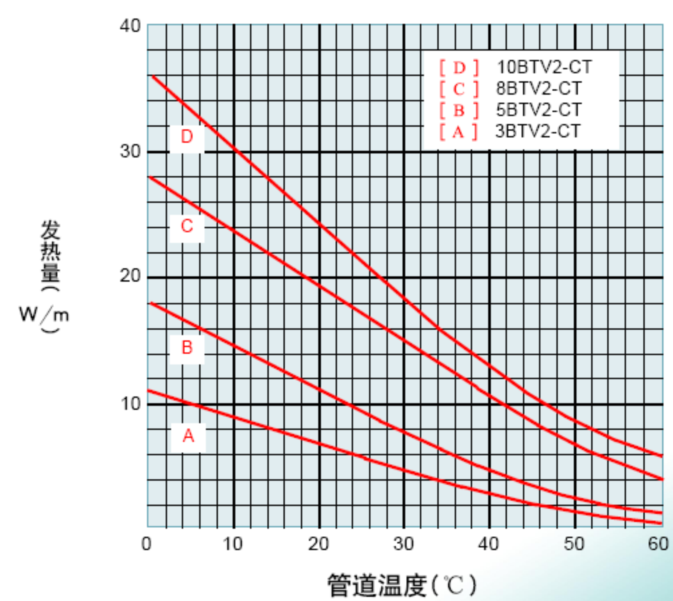

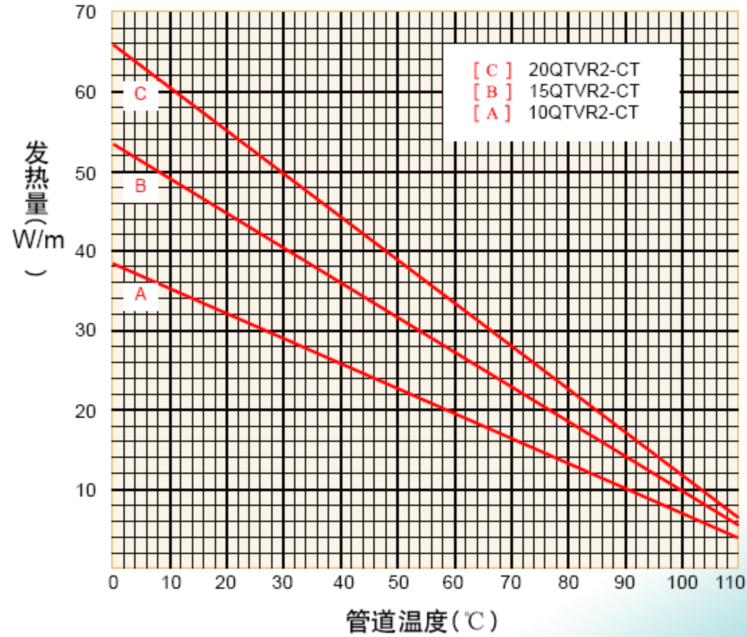

► Heating Cable Selection

﹡The heating cable with thermal output greater than the heat loss at the pipe maintenance temperature.

﹡The Maximum intermittent exposure temperature of pipe dose not exceed the maximum allowable heating cable sheath temperature.

► Determing the Total Length of Heating Cable

﹡Calculate the total length of heating cable for the piping.

﹡Calculate the total length of heating cable for the valves.

﹡Calculate the total length of heating cable for the pipe supports.

﹡Calculate additional heating cable for component installation.

﹡Add all the lengths together.

Tianjin TimEast Sub-sea Pipeline Testing And Service Limited subsidiary company of TimEast group was developed on 2012. We perform process and pipeline pre-commissioning and commissioning service.